More Technology Opportunities in Food Safety and Quality

The Food & Beverage industry is accelerating its digital transformation. The industry is seeing improvements in quality, production, revenue, and other areas due to the digital journey thus far. In our last interview we spoke with Rob Wallace, VP of Product Management, about several technologies that are transforming the Food Safety & Quality (FSQ) digital journey. In our follow-up interview with Rob, we’ll explore several more technologies that are, or can, contribute to the digital journey.

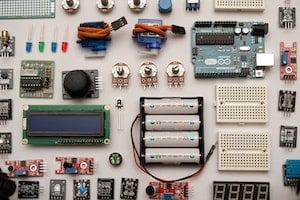

A couple of technologies that I’ve worked with, including one where I thought the engineer was kidding, have caught my attention for FSQ. My experience with the technologies is outside of FSQ but, like many technologies, there is applicability to many use cases. For this blog let’s look at Computer Vision, Electric Noses, and IoT.

What about computer vision has caught your attention?

I’ve employed computer vision in a couple of different use cases. Most recently, getting AI/ML (Artificial Intelligence/Machine Learning) Computer Vision to recognize parts: The front, back, sides, top, etc. And to recognize damage to a part. Automated Visual Inspection Systems are becoming increasingly adopted commercially.

I’ve employed computer vision in a couple of different use cases. Most recently, getting AI/ML (Artificial Intelligence/Machine Learning) Computer Vision to recognize parts: The front, back, sides, top, etc. And to recognize damage to a part. Automated Visual Inspection Systems are becoming increasingly adopted commercially.

Another application of computer vision is to count pills being dispensed in an automated dispenser. Turns out it's excellent automation for getting the right amount of medication into a bottle.

In Food Safety and Quality, we can use computer vision to monitor the size, shape, thickness, and color of our food production, 24x7, with high uniformity. And it doesn’t need vacations. We can adjust to monitor extended frequencies, like infrared, so temperature monitoring is possible. This could offer a non-invasive way to measure log-kill.

Apparently, when you first heard about electronic noses you didn’t know they were real?

The first time I heard about this, some years ago now, I thought the R&D engineer was kidding. It turns out that volatile organic compounds are produced and picked up by our blood due to illness, medications, and some foods. From our blood, they get transferred into the air via our lungs, and exhaled when we breathe out.

The first time I heard about this, some years ago now, I thought the R&D engineer was kidding. It turns out that volatile organic compounds are produced and picked up by our blood due to illness, medications, and some foods. From our blood, they get transferred into the air via our lungs, and exhaled when we breathe out.

We can detect those VoC’s with "electronic noses," to assist in disease diagnosis or assess drug absorption. We’ve all read stories about the dogs that can predict seizures in people, we believe through smell and behavior.

In Food Safety & Quality we can use electronic noses to detect E. coli and Listeria monocytogenes on food. Foodborne pathogens present in food odors, just like in our breath. Imagine the non-invasive uses for our business. We could pass foods by a sensor, for spoilage, contamination, and foreign objects.

You have had years of experience with IoT. What possibilities do you see for its use in FSQ?

Around 2009, IoT was at an inception point. Within a year it was estimated we had 800 million IoT devices in use commercially. I was an early pioneer: One of my patents is in IoT, from work I was doing in healthcare technology in 2011.

Around 2009, IoT was at an inception point. Within a year it was estimated we had 800 million IoT devices in use commercially. I was an early pioneer: One of my patents is in IoT, from work I was doing in healthcare technology in 2011.

Fast forward to 2025, and estimates predict that 30 billion to 42 billion IoT devices will be in use. That’s about a 5000% increase in 16 years. From doorbells to Apple AirTags, IoT is everywhere. I used to joke that we’d know the future had arrived when IoT and toasters merged. I think that happened in 2017.

It's not a joke to me now. Our industry needs to pull data out of legacy food product systems.

In another patent, I was early in recognizing that you could get data out of a legacy system that may not otherwise be suitable for sharing data. In this particular use case, it was about tracing hand hygiene in healthcare settings, with dispensers that were decidedly “not smart” or “not internet capable.” We were turning siloed soap & gel dispensers into enterprise data collection devices to support infection control, by pushing the data to the cloud.

This is exactly what we can do today with IoT connected to legacy PLC (programmable logic controllers), i.e. the electronics that run your oven, production line, washers, dryers, bottling machines, etc. Engineers have figured out how to pull the electronic signals off the “circuit boards” and push them to the cloud.

Would you like to see the performance of your enterprise’s legacy ovens or cookers in a web browser? We are there today. No need to scrap your old oven or cooker. Snap on a IoT reader (or wire in) and eureka! The future is now.

What is your overall takeaway, with these technologies in mind?

FSQ is at an exciting juncture. The digitalization of our industry has many advantages for us. In addition, some of these technologies have been around for years in adjacent industries. What a great 2023 technology portfolio to draw from, to join that digital journey and save time, money, and lives. I couldn’t be more excited about what we can do as technologists in FSQ.

Stay curious,

Rob

Want to share, or comment on the technologies mentioned by Rob?

.jpg)